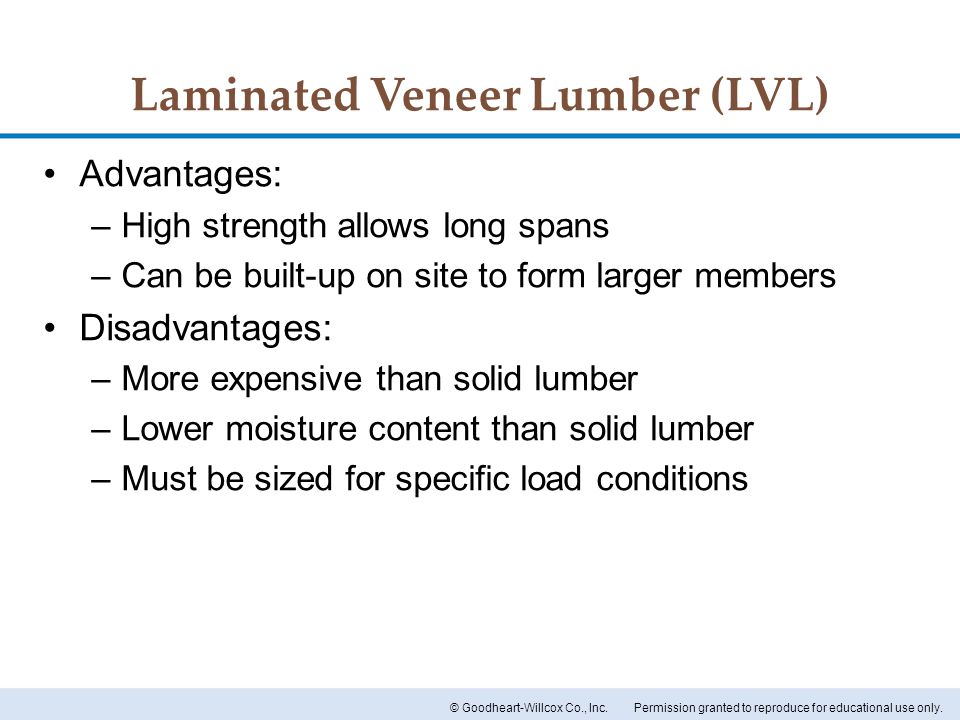

Laminated Veneer Lumber Lvl Disadvantages

Versa lam laminated veneer lumber lvl beams and headers eliminate twisting shrinking and splitting and deliver flatter quieter floors and structures.

Laminated veneer lumber lvl disadvantages. Laminated veneer lumber lvl is a type of high strength engineered timber that can be used as an alternative to solid timber concrete and steel for structural applications. They can also be awkward to sling or fork for the same reason. 2012 design of reinforcement around holes in laminated veneer lumber lvl beams world. They cut pine aspen and other soft woods into strands less than one foot long then pressure bond them using a waterproof adhesive.

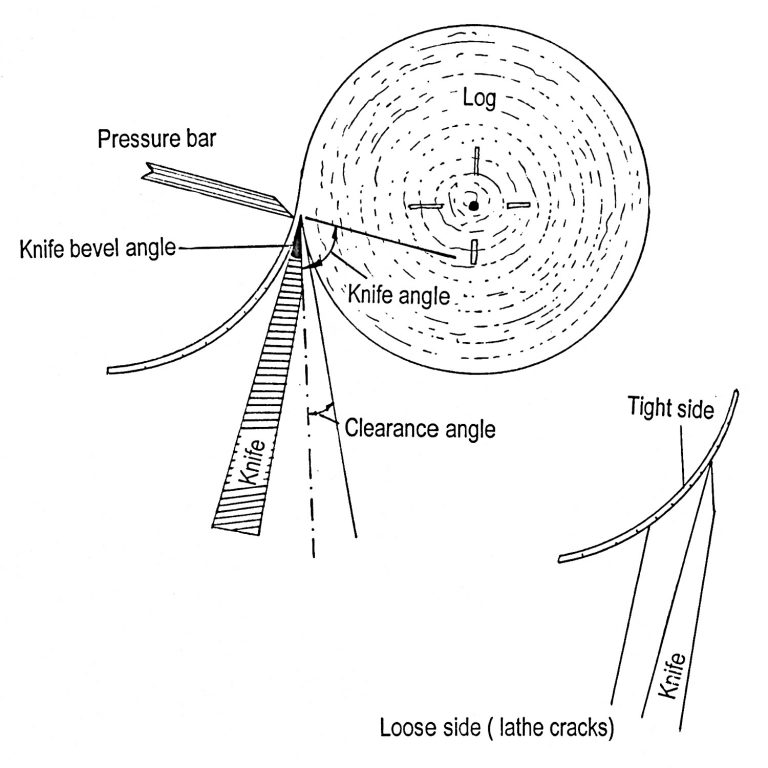

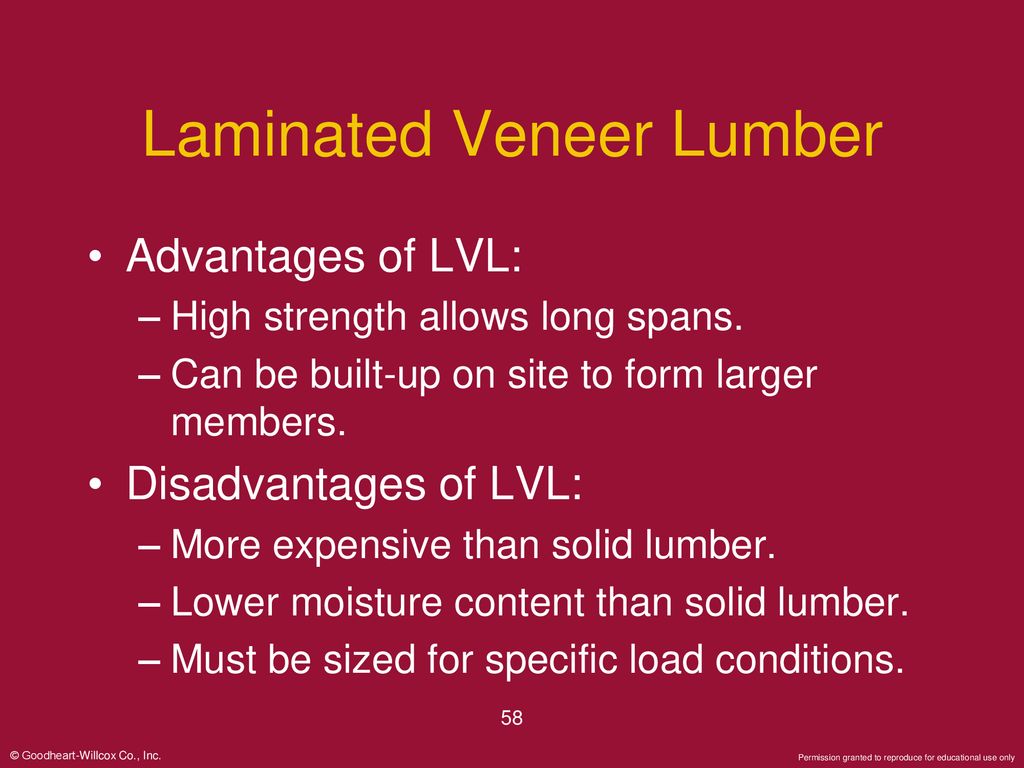

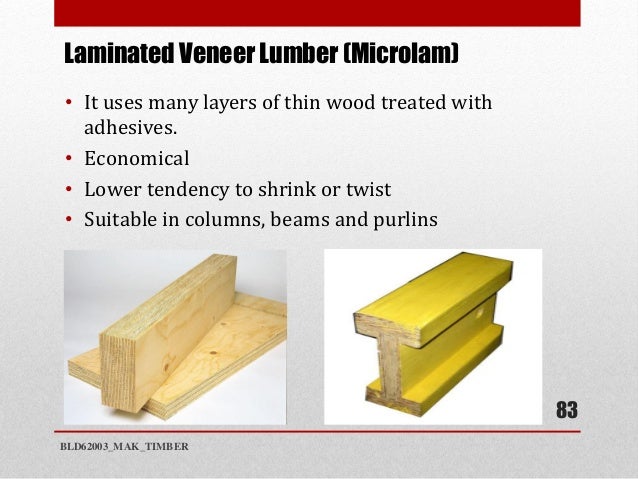

On laminated veneer lumber lvl beams with holes and different methods of reinforcement of the holes journal of structures and buildings under review. It is manufactured by bonding rotary peeled or wood veneers that have been sliced thinly under heat and pressure. This contrasts with plywood in which the grain orientation of adjacent layers is perpendicular most manufacturers use sheets of 1 10 to 1 6 in 2 5 to 4 2 mm thick veneer. Laminated veneer lumber lvl is manufactured from layers of veneer with the grain of all the layers parallel.

Engineered wood products ewp lvl span and size charts. First developed in the 1970s lvl is used as a cost effective and sustainable building. Enhancement of strength properties of lvl by densification of veneer during the press is very limited. Laminated veneer lumber lvl studs can be two times stronger in compression and tension than standard framing lumber of the same dimension.

Shop menards for great selection of laminated veneer lumber that can be used as headers or as floor and ceiling beams. Laminated veneer lumber lvl strand lumber at menards whoops. Hard to drive. Long thin pieces are a pain to carry around even with two or more people because they flop around a lot.

Our versa lam lvl is manufactured in either alexandria lena louisiana in eastern united states or in white city oregon for the western united states. Available in longer and deeper dimensions. Vi conference papers ardalany m fragiacomo m deam b. Recently i built a home with all lvl studs for a client who wanted the home to withstand wind and shear loads.

First developed in the early 1970 s laminated veneer lumber lvl is a high strength engineered timber product formed by assembling wood veneers thin sheets of wood that are uniformly thick. Although its dimensional stability is better than solid wood the product may result in some defect such as warping if it is not properly stored in the warehouse. Laminated strand lumber is good for the environment and builders alike.