Laminated Veneer Lumber Advantages And Disadvantages

So in the future can affect the quality of the frame contribute to the stratification of laminated veneer lumber and its deformation which ultimately will affect its heat saving properties.

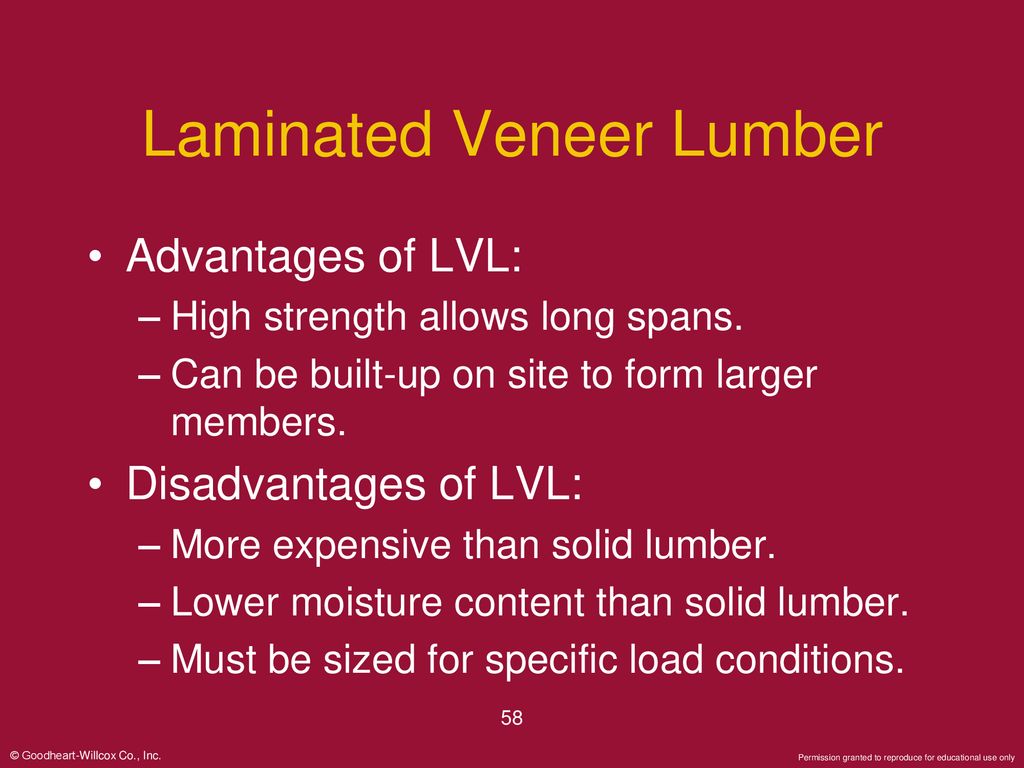

Laminated veneer lumber advantages and disadvantages. Calling glued laminated timber an environmentally friendly material can be a stretch. Laminated veneer lumber lvl studs can be two times stronger in compression and tension than standard framing lumber of the same dimension. Although its dimensional stability is better than solid wood the product may result in some defect such as warping if it is not properly stored in the warehouse. Although its main component is wood it also uses an adhesive base which in many cases is far from perfect.

It is easier to install than many traditional surfaces. It is easy to clean. A disadvantage of using laminated veneer lumber is that it may not be as sturdy as solid lumber. Wood veneer is a very thin slice of wood which is obtained from a tree log.

It is also tested against as nzs 4357 structural laminated veneer lumber and suitable for working stress design in accordance with as 1720 1 1988 saa timber structures code part 1. It is glued on to different types of engineered woods such as plywood mdf blockboard particle board etc. Conversely lvl has several disadvantages as wood composites. To give a finishing and decorative look.

Another disadvantage is the use in its production adhesive of low quality. Recently i built a home with all lvl studs for a client who wanted the home to withstand wind and shear loads. In addition to being flat and straight engineered studs are strong. Laminated veneer lumber lvl is a type of high strength engineered timber that can be used as an alternative to solid timber concrete and steel for structural applications.

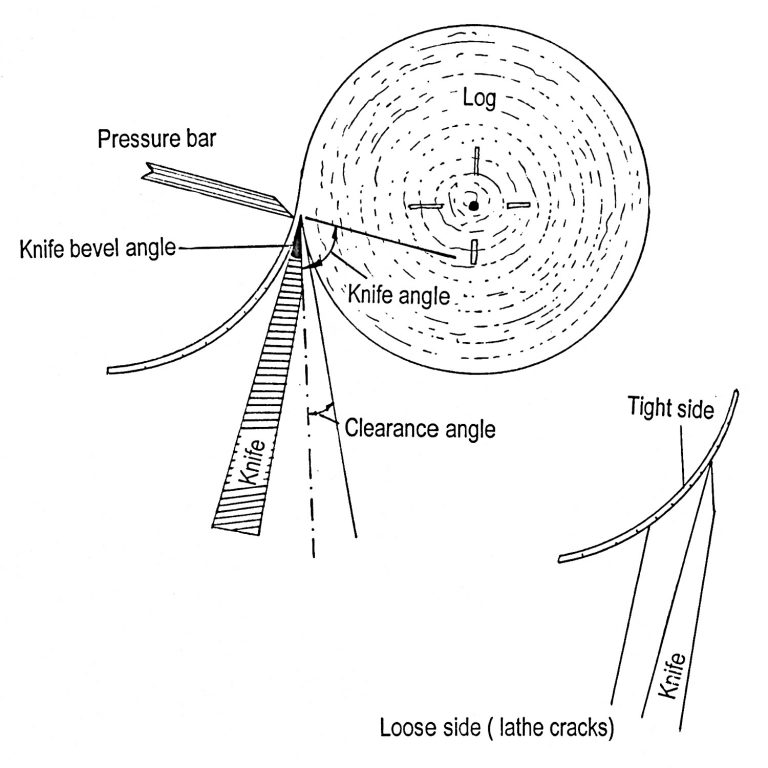

Laminated veneer lumber lvl designing buildings wiki share your construction industry knowledge. This is pieced together and may not last as long as real hardwood. These disadvantages of the house of laminated veneer lumber today almost leveled. It is manufactured by bonding rotary peeled or wood veneers that have been sliced thinly under heat and pressure.

The disadvantages of houses made of laminated veneer lumber perhaps in the construction of housing from glued wood there are only a few drawbacks.