Lamination Technology Student

This includes the design process gear systems electronics cams printed circuit boards pic microcontrollers computer control key words.

Lamination technology student. Laminating technologies specializes in section 10 toilet compartments and manufactures plastic laminate phenolic and solid plastic partitions. Lamination in technology the process of building up successive layers of a substance such as wood or textiles and bonding them with resin to form a finished product. As the times change laminating technologies is committed to the innovations and creativity that the 21st century will bring in our industry. The two layers are fed into a roller press with the laminate film as the top layer.

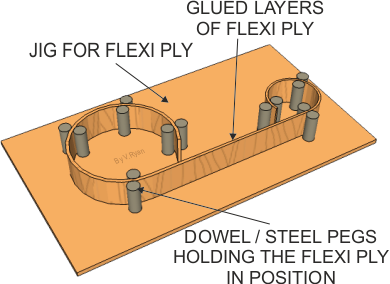

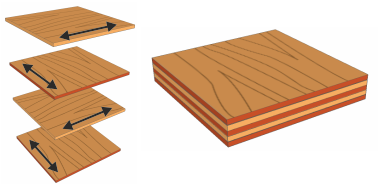

Lamination is a processing approach to producing a composite system with improved strength stability and appearance by using two or more materials stacked in multiple layers. Width of 4 and 5 feet. The laminating process has become ubiquitous on converting machines. After approximately twenty minutes the wood fibres can be reclaimed and recycled.

It s hard to find a paper film or foil product that isn t a laminate whether the layers are from adding coatings or combining two or more substrates. It was an innovative design when introduced in 1956. Laminate technologies specializes in supplying custom laminated sheet stock and fabricating solutions. What is laminated card.

Packaging manufactured from laminated card is made up of paperboard 73 plastic 22 and aluminium foil 5. We offer a very broad range of core options as substrates for our panel products sourced globally including. A diagram of an eames chair is seen opposite. Similarly laminated fabric consists of two or.

Welcome to the only design and technology and engineering website you will need. Pdf file click here for printable worksheet. The head rest back rest and seat are manufactured from layers of veneer forming the curved shapes. Syed ali ashter in thermoforming of single and multilayer laminates 2014.

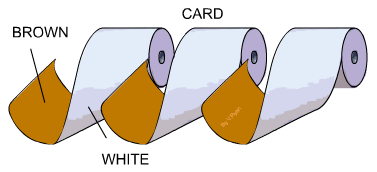

The top heated roller is lowered on to the card laminate layers as they are automatically fed into the roller press. This process fuses a heat sensitive polyethylene film to the surface of card. The hot lamination process. Recycling of laminate card tetra packs are recyclable into products such as egg boxes paper bags envelopes and writing paper.

Lamination has become a regular part of the converting process. The used cartons are placed in a pulping machine which contains water. Hundreds of pages cover most aspects of design and technology and engineering whether you are a pupil or a teacher.