Lamination Stacking Process

Economical large scale production is a further plus.

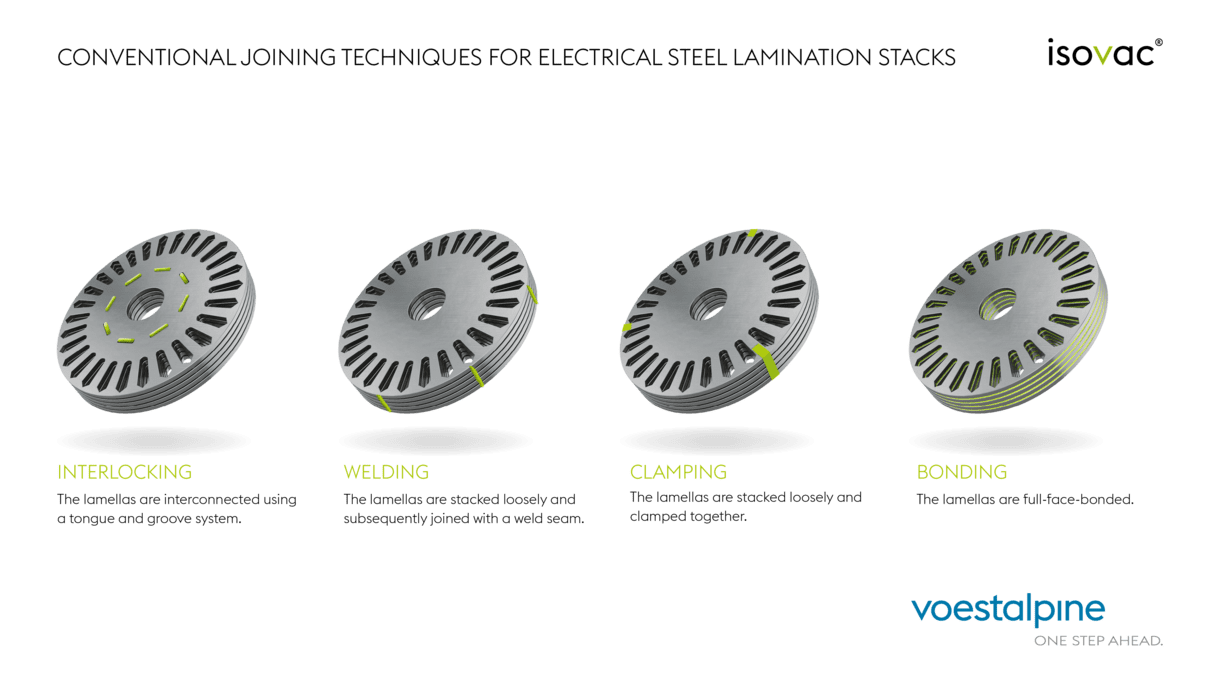

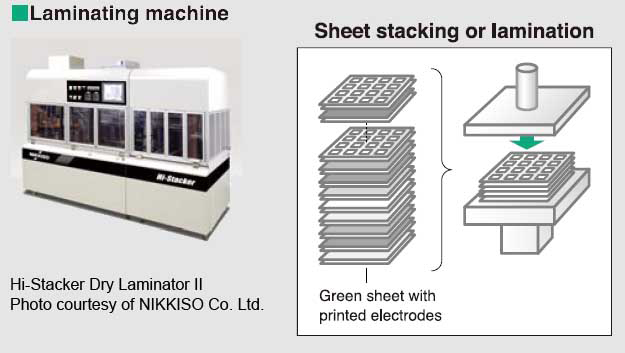

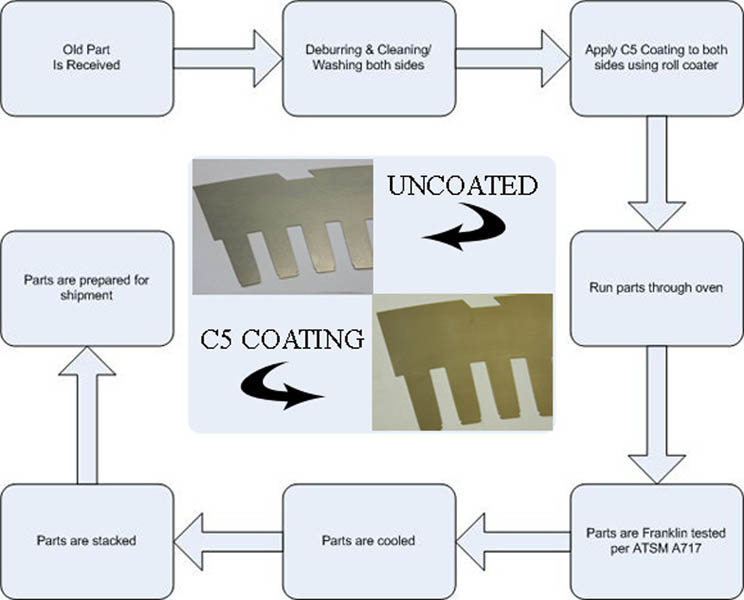

Lamination stacking process. Electric motor lamination stacks. Then the sheets are stacked on an aligning fixture and pinned or welded together to produce the magnetic cores. Each lamination is carefully stacked to the specified height 1 lamination. Manufactured using the premium electrical steel of voestalpine with a new full surface bonding process compacore lamination stacks guarantee improved electromagnetic and motor properties.

Rotor and stator lamination assemblies magnetic circuits for motor and generator. The parameters for single stack process pressure mode hot start have been. Over 30 million press strokes per day allows output of over 300 tons finished magnetic circuits laminations each day. High speed presses ranging from 100 tons to 800 tons.

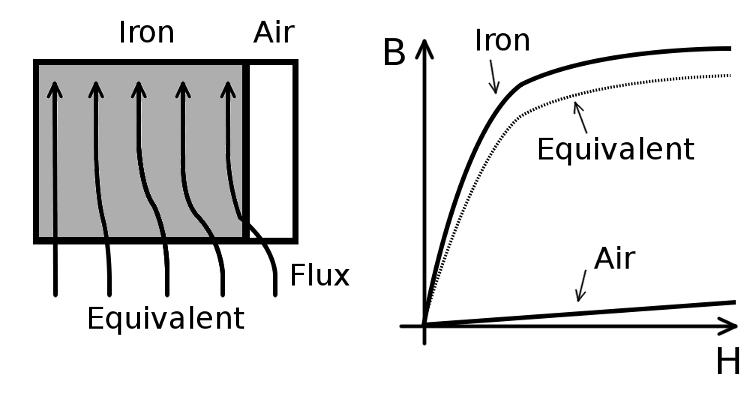

Compacore for the next level in electric motors. Since the 1940 s customers throughout the world have relied on danco as a quality supplier for laminates cores and stacks for their electric motors. Without any press pads a maximum temperature of 311 320 f 155 160 c should be considered. Lamination sheet to prevent eddy currents from traveling between the sheets.

After that the lamination sheets are shaped by the stamping process in either a progress or a single station die. Each stack is aligned using precision gage pins that are accurate to the 0001 once stack height is achieved laminations may be bonded or welded depending on your application. Danco manufactures builds and assembles stamped laminations and core and stack assemblies to customer specifications. Feintool is also constantly breaking new ground in the field of electric motor lamination with a key focus on the development of new technologies materials products and processes.

From the begining we have focused on technologies and processes to produce hgh performance stator and rotor lamination stacks from electrical sheet. Lamination stacking and assembly by welding riveting cleating bonding etc stamped and laser cut laminations stator lamination rotor lamination transformer lamination armature lamination pole lamination sand and recoat finger plates vent plate manufacture and assembly shaft manufacture and assembly. Lamination is the technique process of manufacturing a material in multiple layers so that the composite material achieves improved strength stability sound insulation appearance or other properties from the use of the differing materials such as plastic a laminate is a permanently assembled object created using heat pressure welding or gluing.