Laminating Resin Catalyst Ratio

Quart uv cure polyester.

Laminating resin catalyst ratio. This is a dual cure mekp or uv cure formulation. Gel coat is sticky all over after hardener has been mixed into the resin and proper cure time has elapsed. Add 2ml of catalyst per 100 g of resin and stir thoroughly. Flowcoat will give a coverage of approx 0 5 0 75kg m i e.

1 kg of flowcoat will cover approx. Resin to glassfibre ratios. This resin also has low styrene emissions lse making it ideal when working in a factory or confined space. All resins whether for casting or laminating require the addition of catalyst hardener and accelerator if the resin is not pre accelerated to initiate the curing process.

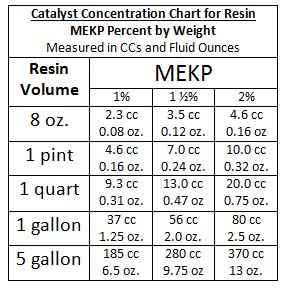

Use 12 drops of hardener per ounce of resin. Adding more of less of the catalyst agent will speed up or slow down the curing time for the resin. Catalyst chart volume of catalyst to be used with polyester resins methyl ethyl ketone peroxide percent by weight 1 1 25 1 5 1 75 resin 1 volume drop cc oz drop cc oz drop cc oz drop cc oz 4 ounce 32 1 1 4 1 32 40 1 1 2 3 64 48 1 3 4 1 16 56 2 1 16. Resin liquid catalyst mekp na2 ml 50 g.

When combined with a reinforcement fabric resin serves two primary purposes. For an effective laminate it is essential that the glassfibre material is thoroughly wetted out with resin. First resin holds the reinforcement fabric together while helping it conform to the desired shape. The ratio of resin.

Pint uv cure laminating resin. Fibreglass is approximately 2 5. Polyester resins require a catalyst to cure or harden. Stir thoroughly 30 mixes to the left and 30 mixes to.

When used with catalyst mekp add to resin at ratio of 1 by weight approx. And often complex mix ratio. Preparing resins for casting or laminating. To quart this resin is also a good choice for the home builder who wants better control over gel times.

Incorrect mixing ratio was used when combining gel coat and hardener. Of catalyst to resin 4 catalyst 3 catalyst 2 catalyst 1 catalyst temperature 5 13 c 13 16 c 16 20. Guidelines for estimating resin to fibreglass ratios. Whilst others new to laminating will use more resin this will effect the weight of the panel and.

2 by volume or weight. The ratio range for catalyst to resin is 1 to 2 percent hardener to the total volume of resin to be used. Laminating resin lse is an orthophthalic based resin ideal for all general purpose applications. Laminating resins begin as a liquid and cure into a solid form.

1 ml at 2. 1 i e 1 kg of fibreglass requires approx. Catalyst should be added at between 1 and 4 by weight depending on ambient conditions and cure time required. Use a safety dispenser bottle to add 20ml of catalyst per 1kg of resin.