Laminating Process Technology Student

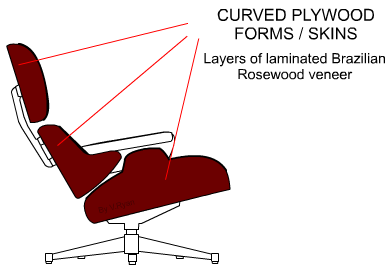

Laminated veneer and plywood parts manufacturing the eames lounge chair laminated parts components.

Laminating process technology student. Laminated wood is suitable for the head rest back rest and seat of the eames chair. Manufacturing laminated wood is made from many thin strips of wood. Students to create a fact file on wood lamination joining methods for plastics metals and adhesives. Laminated cartons are used to store liquids such as milk and pure orange juice for up to a year.

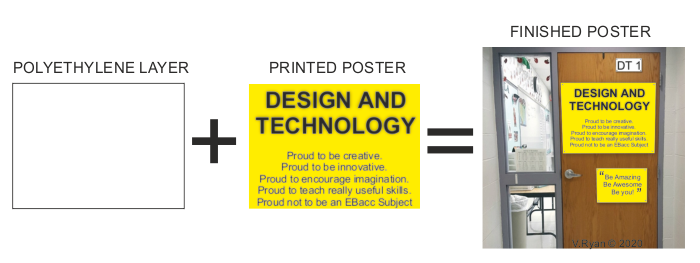

This type of carton is composed of paper card and layers of polythene keeping the contents fresh and hygienic. Complex shapes can be achieved with one piece of laminated material. This process joins a card layer with a layer of clear polyethylene which as an adhesive side. Injection moulding the manufacturing process robin day.

Plywood is a common example of laminated wood though it is not the only product created through the wood laminating process. All these posters have being processed through the commercial laminating. Is strong sets slow and resistant to weather and preservatives. Laminated board for example consists of thin layers of wood bonded together.

Adhesives glue for laminating pva polyvinyl acetate. The natural wood gives a quality finish. Forming technologies wood laminating is the process of forming multiple sheets of veneer chips or solid timber using moulds and bonded together by very strong adhesives to produce rigid lightweight structures. In sweden over 130 billion tetra paks are manufactured each year.

Lamination in technology the process of building up successive layers of a substance such as wood or textiles and bonding them with resin to form a finished product. The sections are intended to provide a valuable engineering design and technology resource for all and they are free. When thin layers of veneer are glued together forming one part they are called laminates. Students to investigate joining methods for plastics and metals.

Rolling steel and welding the barcelona chair basic stages of manufacture. As the card laminate layers are fed through the cold rollers they are joined permanently due to the clear adhesive on the polyethylene. The cold lamination process. The most famous laminated cartons are manufactured by tetra pak.

This includes the design process gear systems electronics cams printed circuit boards pic microcontrollers computer control key words phrases structures vocational work technology and cultures basic cnc work. Design responses about materials processes wood laminating. Steaming natural wood and forming the thonet no14 chair construction techniques. These strips of wood are carefully sanded down so that the surfaces.

Is strong and is not expensive. Similarly laminated fabric consists of two or. Often these strips are cast offs or mixed from a variety of different types of wood.