Laminating Gel Coat Mold Release

Applied without the use of a mold release agent 105685 the surface will remain tacky.

Laminating gel coat mold release. Third apply fiber glass. The product cures to a tacky finish for re coating. When we talk about gelcoat from moulds we refer to a resin based compound to which pigments have been added that determine its colour various inert charges and finally agents that can give the necessary thixotropy that is the possibility of allowing the application of different layers of paint in thicknesses that are also important in. You can wait 24 hours or continue building your project immediately the gel coat will not cure until it is sealed in the mold by your fiberglass layers.

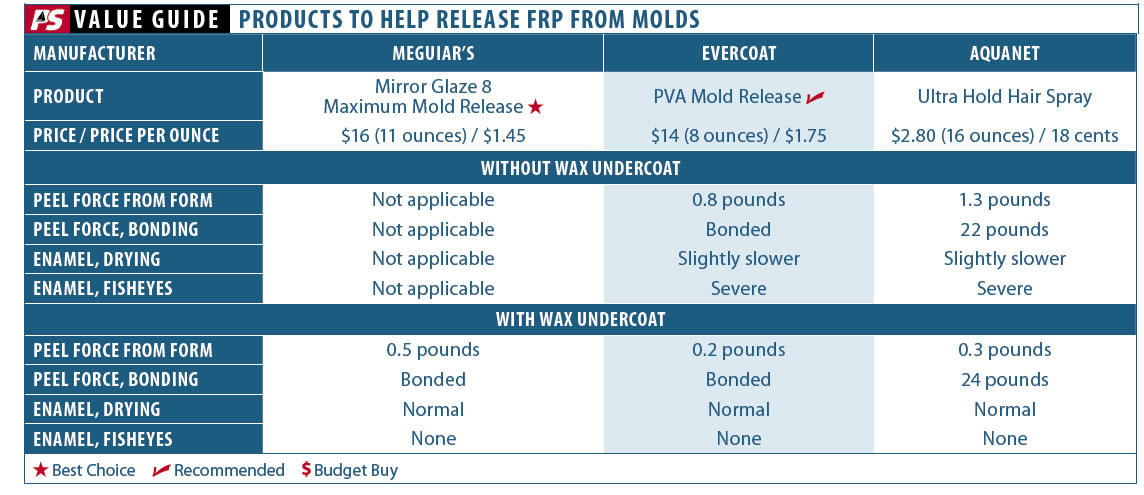

The quality iso npg marine laminating gel coat to permanently repair or replace original high glass finish. There is no universal best mold release says nancy teufel technical support manager for axel plastics research laboratories. The quality iso npg marine laminating gel coat to permanently repair or replace original high gloss finish. Mold release provides the critical barrier between a tooling surface and the materials used to build up a part laminate enabling separation of the cured part from the mold.

Epoxacoat red is a thixotropic epoxy gel coat that is widely used for hand laminating tooling applications. Apply another layer of the laminating gel coat and follow with a mold coverage cure times application suggestions. For best results it. Hi david as long as the is no damage to the glass beneath the gelcoat it s a pretty simple fix just repair the individual spots.

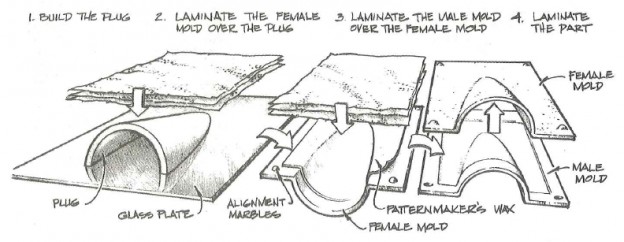

Evercoat mold release 105685 must be used to attain a fully cured surface. Adjust the catalyst level to slow down or speed up gel time. And or paste wax mold release tooling gel coat fiberglass mat woven roving stitchmat knytex or equivalent marine laminating resin resin roller brush acetone for cleanup containers for mixing resin and gel coat catalyst plastic or metal container for acetone. Epoxacoat grey epoxacoat grey is a thixotropic epoxy gel coat that is widely used for hand laminating tooling applications.

Useful for moulding or making moulds. The higher the percentage of hardener the faster the gelcoat. Gel time depends on amount of catalyst admixed. This gel coat is a laminating gel coat and it is designed to remain tacky between layers for easy re coating.

You can apply gel coat with a brush if you are building a fiberglass project in a mold. Evercoat mold release 105685 must be used to attain a fully cured surface. Proper catalyzation is imperative for proper cure when using polyester. The product cures to a tacky finish for re coating.

Cooler temperatures may require a higher percentage of catalyst than warmer temperature conditions.