Laminated Veneer Lumber Spedcs

Made in a factory under controlled specifications it is stronger straighter and more uniform.

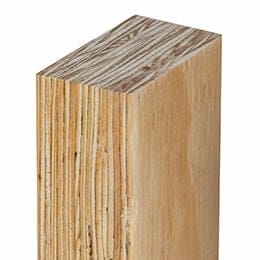

Laminated veneer lumber spedcs. Laminated veneer lumber lvl lvl is a widely used structural composite lumber product. Made in a factory under controlled specifications it is stronger straighter and more uniform. It is typically used for headers beams rim board and edge forming material. Lvl properties significantly exceed those of solid wood glulam and high grade timber.

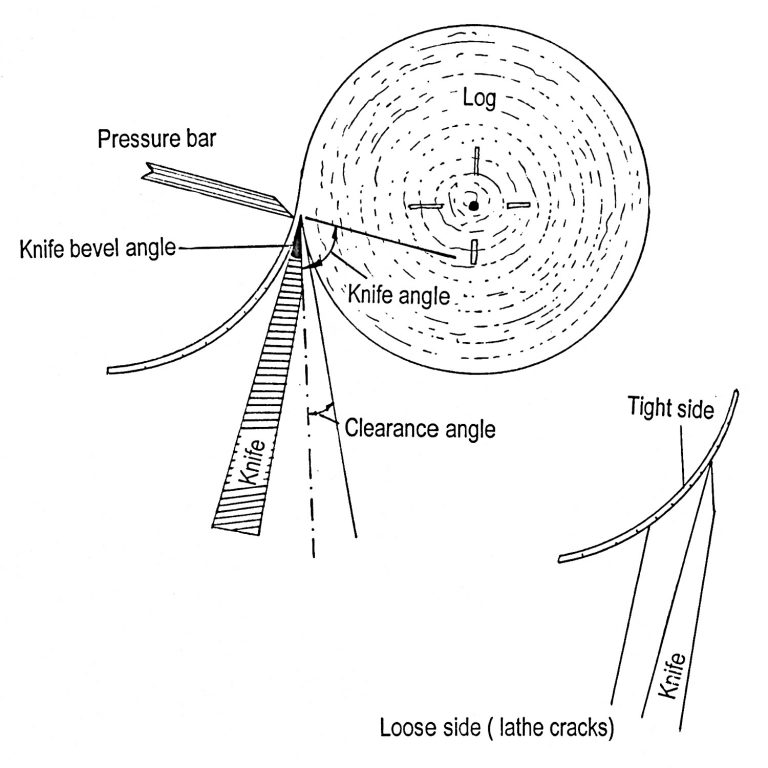

Lvl offers several advantages over typical milled lumber. Due to its composite nature it is much less likely than conventional lumber to warp twist bow or shrink. Lvl is made in a process similar to plywood. The lvl billet is then sawn to desired dimensions depending on the end use application.

Laminated veneer lumber lvl is a general description for an assembly of veneers laminated with an adhesive in which the grain direction of the outer veneers and most other veneers is in the longitudinal direction. Lvl offers several advantages over typical milled lumber. Rotary peeled wood veneers usually pine or fir are dried then laminated together with glue and resins under heat and high pressure to form sturdy consistently reliable framing lumber. Lvl offers several advantages over typical milled lumber.

Our versa lam lvl is manufactured in either alexandria lena louisiana in eastern united states or in white city oregon for the western united states. Versa lam laminated veneer lumber lvl beams and headers eliminate twisting shrinking and splitting and deliver flatter quieter floors and structures. Lvl is similar in appearance to plywood without cross bands. Lpi laminated veneer lumber product specifications design values 2 floor beam quick reference tables 3 combined header quick reference tables 4 roof header quick reference tables 5 uniform floor load plf tables 6 uniform roof load plf tables 7 general information 8 lp lvl 2650f b 1 9e technical guide.

Laminated veneer lumber is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. Laminated veneer lumber is an industry standard in the framing of new buildings and is used to replace solid wood beams and joists in renovating existing buildings. It is produced by bonding thin wood veneers together in a large billet so that the grain of all veneers is parallel to the long direction. Lvl is a type of structural composite l.

1 1 4 inch 1 1 1 2 inch 14. When making a selection below to narrow your results down each selection made will reload the page to display the desired results. Product overview boises laminated veneer lumber lvl is a product that uses multiple layers of thin wood assembled with adhesives. The complex technological process results in a homogenous material with unique performance.

Lvl laminated veneer lumber is a technologically enhanced and improved high strength structural wood based material.