Laminated Veneer Lumber Pros And Cons

So in the future can affect the quality of the frame contribute to the stratification of laminated veneer lumber and its deformation which ultimately will affect its heat saving properties.

Laminated veneer lumber pros and cons. Laminate products are flame retardant and some have antibacterial properties. All you have to do is dust the furniture with a damp microfiber cloth on a regular basis in order. Billets are stripped to a perfect geometric shape. If you re looking for a lasting piece laminate is probably not the best option.

It is glued on to different types of engineered woods such as plywood mdf blockboard particle board etc. No old growth or exotic trees are used to produce laminate flooring. The technology by which glued laminated timber is made. Higher end laminate pieces have a slightly more realistic look but it s not the same as a piece made from real wood.

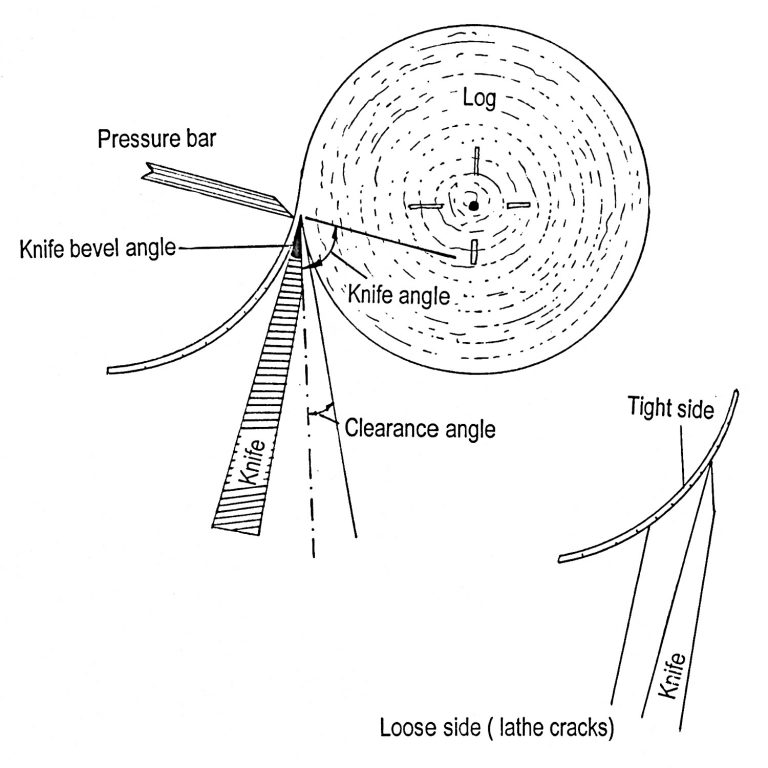

Wood veneer is a very thin slice of wood which is obtained from a tree log. This makes them a great choice for high traffic areas like waiting. Pros of laminate products. Even well made laminate furniture doesn t have the longevity of solid wood pieces.

Where to use it. Many interior designers use wood veneer to improve the aesthetics of kitchen cabinets. If chipped scratched or damaged timber laminate cannot be repaired. Another disadvantage is the use in its production adhesive of low quality.

It also has a high resistance to impact and moisture. They are easy to clean. The wear layer of laminate floor is extremely tough which makes cleanup and maintenance easy. Profiled almost twice cheaper so many people choose it.

B enchtops vertical surfaces and wet areas such as bathrooms. In addition to being flat and straight engineered studs are strong. The boards are treated with special protective compounds. Wood veneer is a process where a thin layer of wood is glued over the surface of some other kind of wood or laminate.

The raw material is spliced to the desired length if necessary. Timber laminate comes in a vast array of wood like finishes and textures and costs less than solid timber and timber veneers. However laminated much more resistant to the appearance of mold mildew. To give a finishing and decorative look.

Snap together laminate flooring eliminates the need for voc releasing glues. However construction of such a timber require lining. The material is glued under high. Occasional sweeping keeps the surface free from abrasive grit.

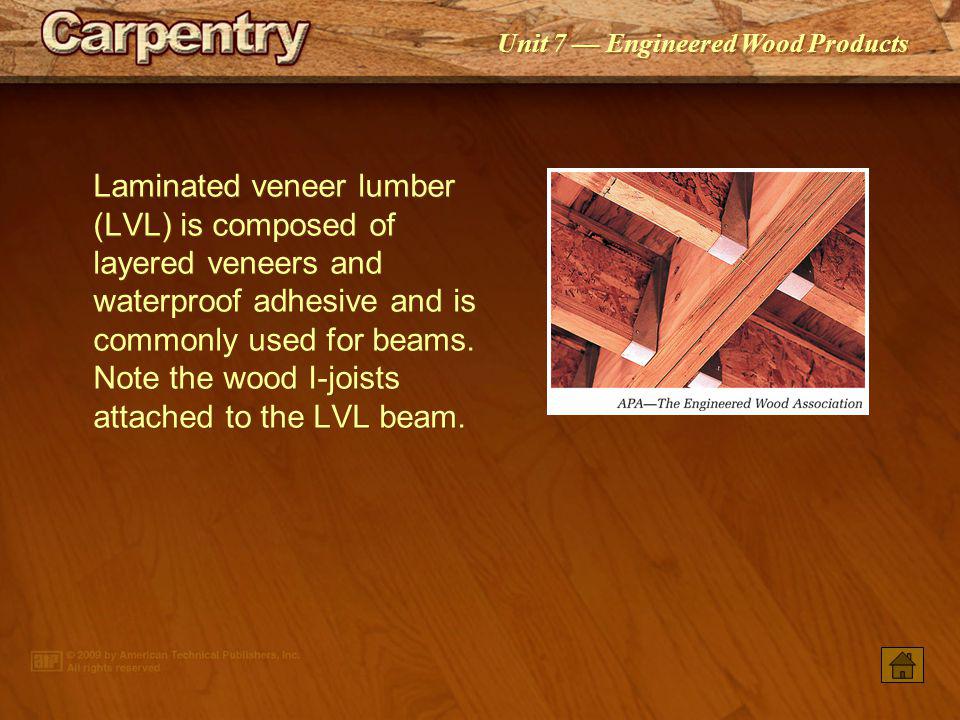

Wood veneer is available in. Laminated veneer lumber lvl studs can be two times stronger in compression and tension than standard framing lumber of the same dimension. These days furniture or other wood products made from veneered lumber are often regarded as being of lesser quality than items made from solid wood. Therefore the cost as a whole together with the finish is no different from the price of laminated veneer lumber.