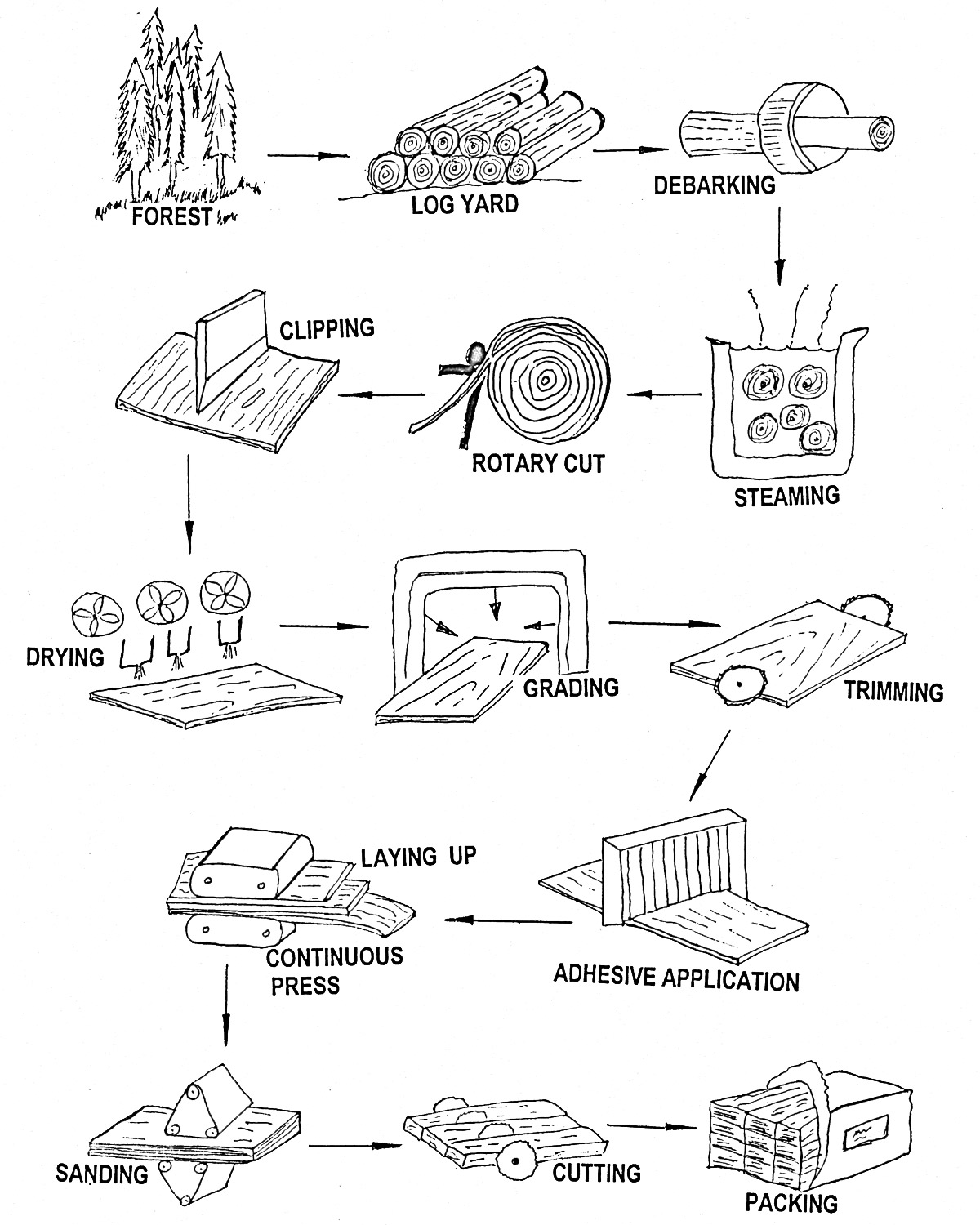

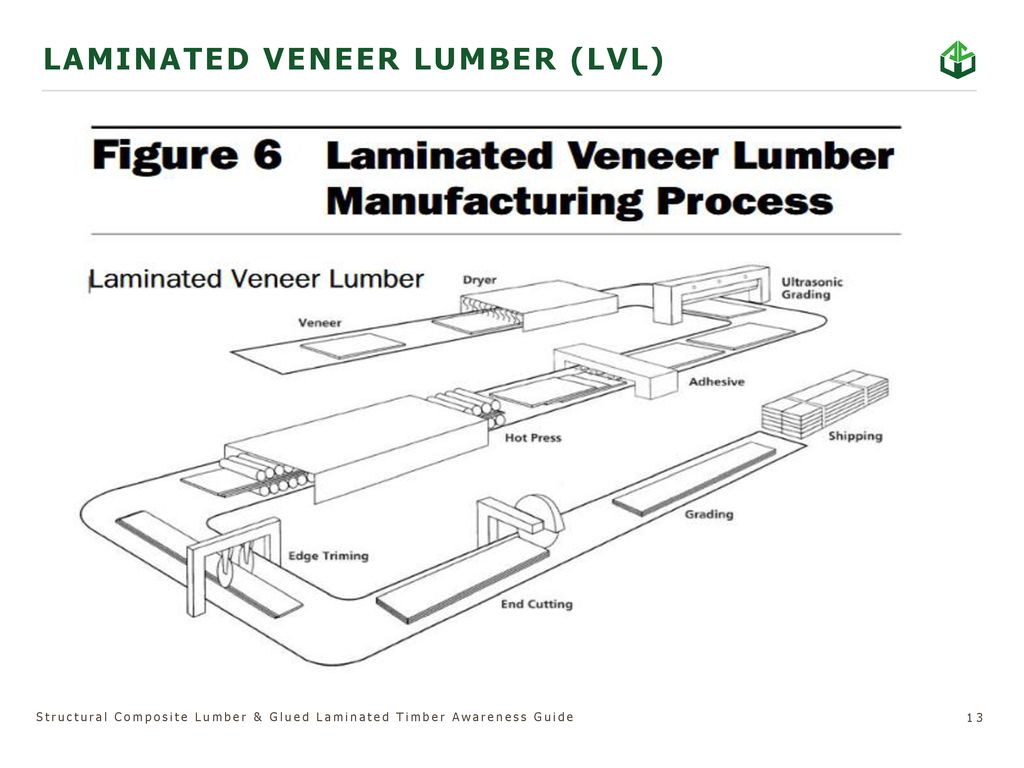

Laminated Veneer Lumber Manufacturing Process

Engineered wood products run the gamut from oriented strand board to plywood to laminated veneer lumber lvl and can be a resilient alternative to solid sawn wood while increasing a project s design potential.

Laminated veneer lumber manufacturing process. Made in a factory under controlled specifications it is stronger straighter and more uniform. Us4844763a laminated veneer lumber lvl google patents. The veneers used to manufacture. Hence it can be considered as a veneer based product.

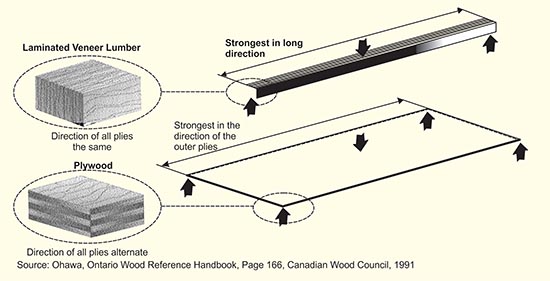

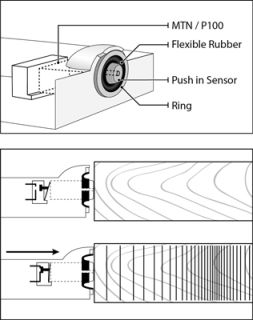

Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives it is typically used for headers beams rimboard and edge forming material lvl offers several advantages over typical milled lumber. Advances in timber technology mean more options for architects and designers seeking sturdy materials for structural applications. Laminated veneer lumber lvl is a layered composite of wood veneers and adhesive. 10 9 2 process description1 10 9 2 1 lvl process description laminated veneer lumber consists of layers of wood veneers laminated together with the grain of each veneer aligned primarily along the length of the finished product.

Lvl is a versatile engineered product and combines the best of modern process technology with the aesthetic beauty of natural wood. It is comparable in strength to solid timber concrete and steel and is manufactured by bonding together rotary peeled or sliced thin wood veneers under heat and pressure. Meet jason the project development manager at nelson pine industries and see how logs of pine are transformed into a strong and durable product called lvl. Laminated veneer lumber lvl is a high strength engineered wood product used primarily for structural applications.

A process of manufacturing continous or indefinite lengths of the composite wood panel is disclosed. The laminated veneer lumber of the present invention has improved dimensional stability and may be nailed without splitting or cracking.