Laminated Veneer Lumber Lengths

Laminated veneer lumber is an industry standard in the framing of new buildings and is used to replace solid wood beams and joists in renovating existing buildings.

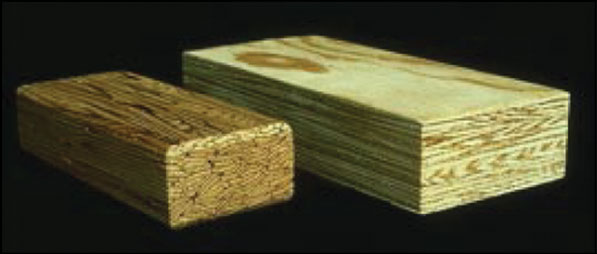

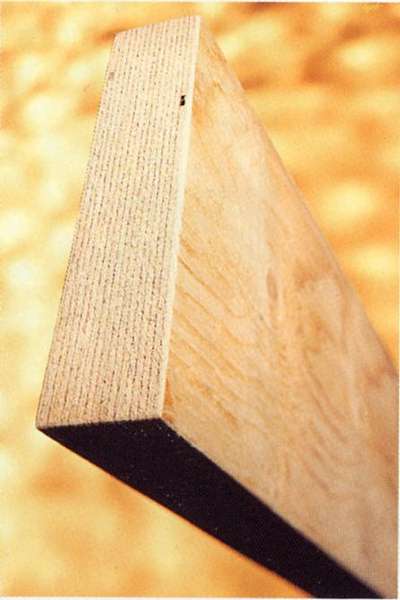

Laminated veneer lumber lengths. It is comparable in strength to solid timber concrete and steel and is manufactured by bonding together rotary peeled or sliced thin wood veneers under heat and pressure. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives it is typically used for headers beams rimboard and edge forming material lvl offers several advantages over typical milled lumber. Laminated veneer lumber lvl lvl is a widely used structural composite lumber product. Having the grain of all veneers run in the same longitudinal direction results in a product that is strong when edge loaded as a beam or face loaded as a plank.

It is produced by bonding thin wood veneers together in a large billet so that the grain of all veneers is parallel to the long direction. Lvl is made in a process similar to plywood. Item 9529 model 2100006. Laminated veneer lumber lvl is manufactured by bonding layers of wood veneers together under heat and pressure using a waterproof adhesive.

Rotary peeled wood veneers usually pine or fir are dried then laminated together with glue and resins under heat and high pressure to. Title a z title z a brand name a z brand name z a. Lvl is the most widely used structural composite lumber scl product and provides attributes such as high strength high stiffness and dimensional stability. Price low to high.

With hychord designers can confidently exploit the excellent strength properties for minimum sections and then utilise the predicted deflection performance to apply just the right amount of camber to ensure flat. When making a selection below to narrow your results down each selection made will reload the page to display the desired results. Laminated veneer lumber lvl is a high strength engineered wood product used primarily for structural applications. Laminated veneer lumber lvl first used during world war ii to make airplane propellers laminated veneer lumber lvl has been available as a construction product since the mid 1970s.

1 75 in x 11 87 in x 20 ft versa lam laminated veneer lumber. The lvl billet is then sawn to desired dimensions depending on the end use application. Lpi laminated veneer lumber product specifications design values 2 floor beam quick reference tables 3 combined header quick reference tables 4 roof header quick reference tables 5 uniform floor load plf tables 6 uniform roof load plf tables 7 general information 8 lp lvl 2650f b 1 9e technical guide. Hychord hychord is a laminated veneer lumber lvl product ideal for truss chords in high load applications where strength and predictable deflection performance are paramount.

Made in a factory under controlled specifications it is stronger straighter and more uniform.