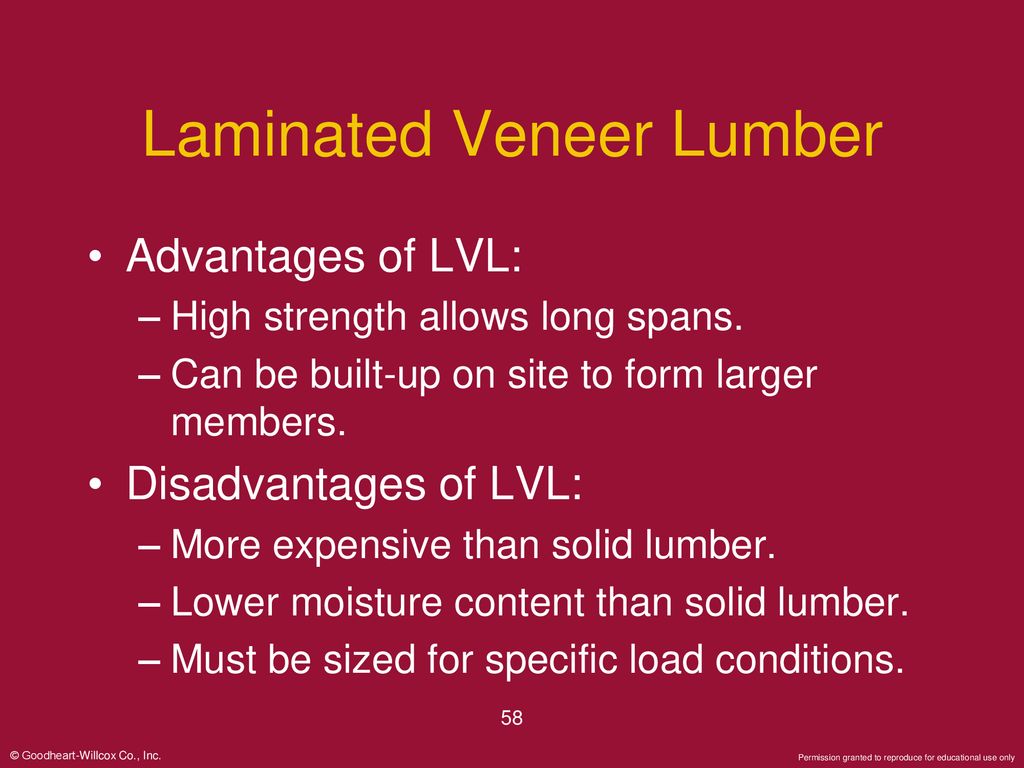

Laminated Veneer Lumber Disadvantages

A disadvantage of using laminated veneer lumber is that it may not be as sturdy as solid lumber.

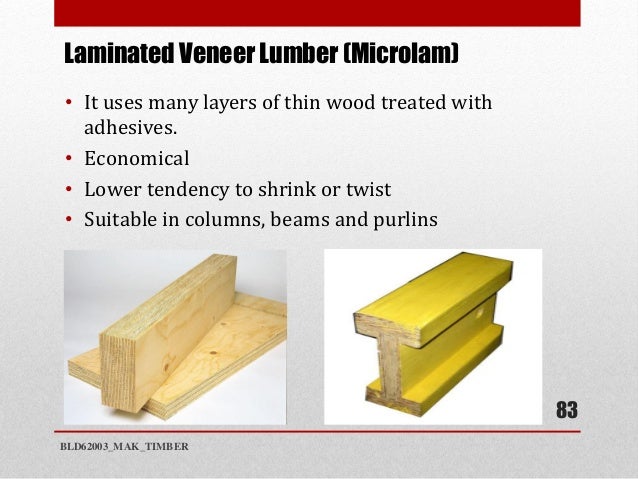

Laminated veneer lumber disadvantages. Recently i built a home with all lvl studs for a client who wanted the home to withstand wind and shear loads. It is a composite product manufactured from multiple thin layers of veneer that are aligned with the length of the finished lumber. When ordering check the glue certificate with the lumber. Calling glued laminated timber an environmentally friendly material can be a stretch.

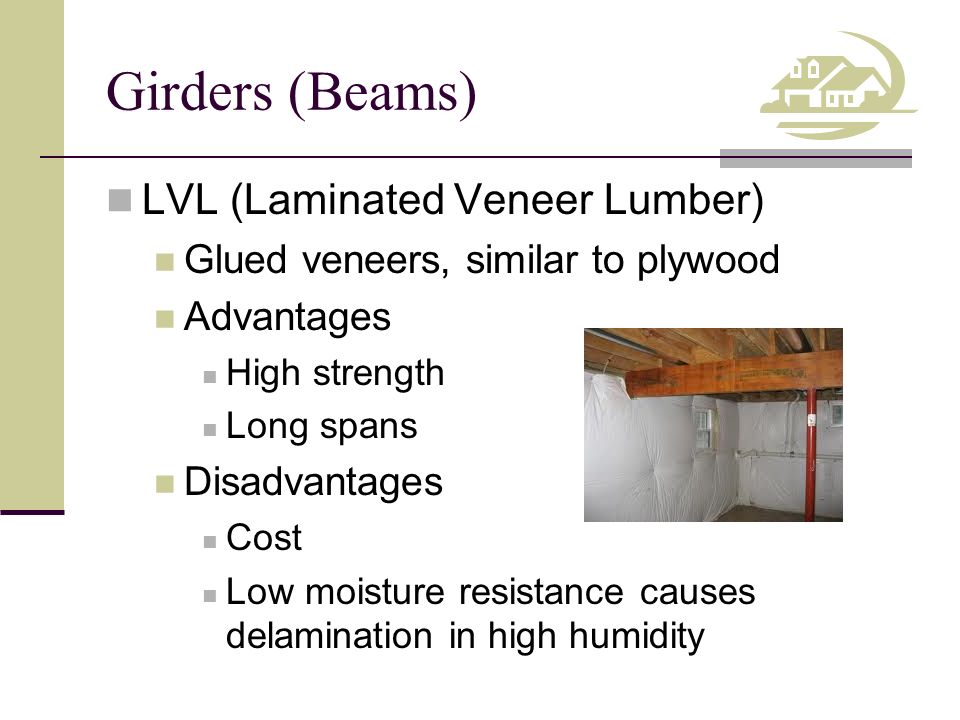

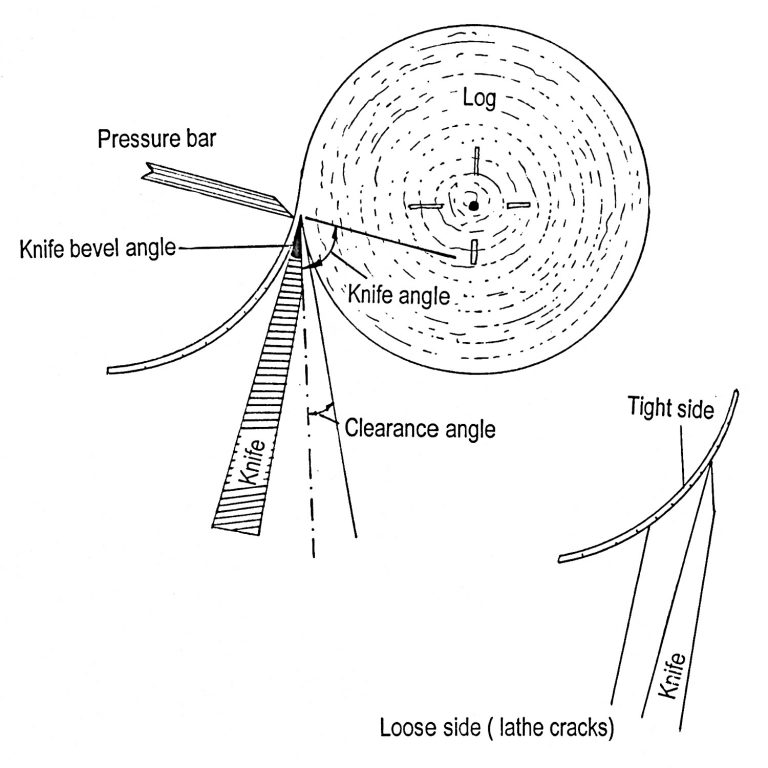

Flanges are made from laminated veneer lumber or laminated structural lumber and range in size from 1 5 16 to 1 1 2 inches thick and from 1 1 2 inches to 3 1 2 inches wide. Laminated veneer lumber lvl is one of the most widely used engineered wood products for constructional applications. These disadvantages of the house of laminated veneer lumber today almost leveled. It is manufactured by bonding rotary peeled or wood veneers that have been sliced thinly under heat and pressure.

The web is typically made of osb oriented strand board and is either 3 8 inch or 7 16 inch thick depending on its application in a residential installation. The client worked with the structural engineer to design a wood framed house that could stand. Although its main component is wood it also uses an adhesive base which in many cases is far from perfect. This is pieced together and may not last as long as real hardwood.