Laminated Veneer Lumber Definition

Kerto lvl delivers its high strength from the homogeneous bonded structure.

Laminated veneer lumber definition. It offers several advantages over typical milled lumber. Laminated veneer lumber lvl first used during world war ii to make airplane propellers laminated veneer lumber lvl has been available as a construction product since the mid 1970s. Glued laminated timber also abbreviated glulam is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable moisture resistant structural adhesives. Our versa lam lvl is manufactured in either alexandria lena louisiana in eastern united states or in white city oregon for the western united states.

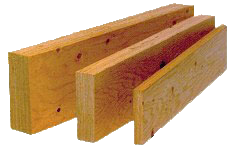

Metsä wood s kerto lvl is a laminated veneer lumber product used in all types of construction projects from new buildings to renovation and repair. In north america the material providing the laminations is termed laminating stock or lamstock. The lvl billet is then sawn to desired dimensions depending on the end use application. Laminated veneer lumber lvl is a high strength engineered wood product used primarily for structural applications.

It is produced by bonding thin wood veneers together in a large billet so that the grain of all veneers is parallel to the long direction. Illustraged in our photographs of lvl beams in use at a poughkeepsie ny project our example lvl beams are made of fifteen laminated wood plies. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. Laminated veneer lumber is an engineered wood product developed in the 1960 s is produced by gluing together layers of wood veneers with the wood grains in parallel.

It is comparable in strength to solid timber concrete and steel and is manufactured by bonding together rotary peeled or sliced thin wood veneers under heat and pressure. The manufacturing process of lvl enables large members to be made from relatively small trees providing efficient utilization of forest resources. It is stronger straighter and more uniform. It is typically used for headers beams rimboard and edge forming material.

Much like plywood thin sheets of wood are sandwiched and bound with super strong glue. Versa lam laminated veneer lumber lvl beams and headers eliminate twisting shrinking and splitting and deliver flatter quieter floors and structures. About laminated veneer lumber lvl as mentioned the generic name for this type of lumber are the initials lvl. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives.

Kerto lvl is incredibly strong and dimensionally stable.