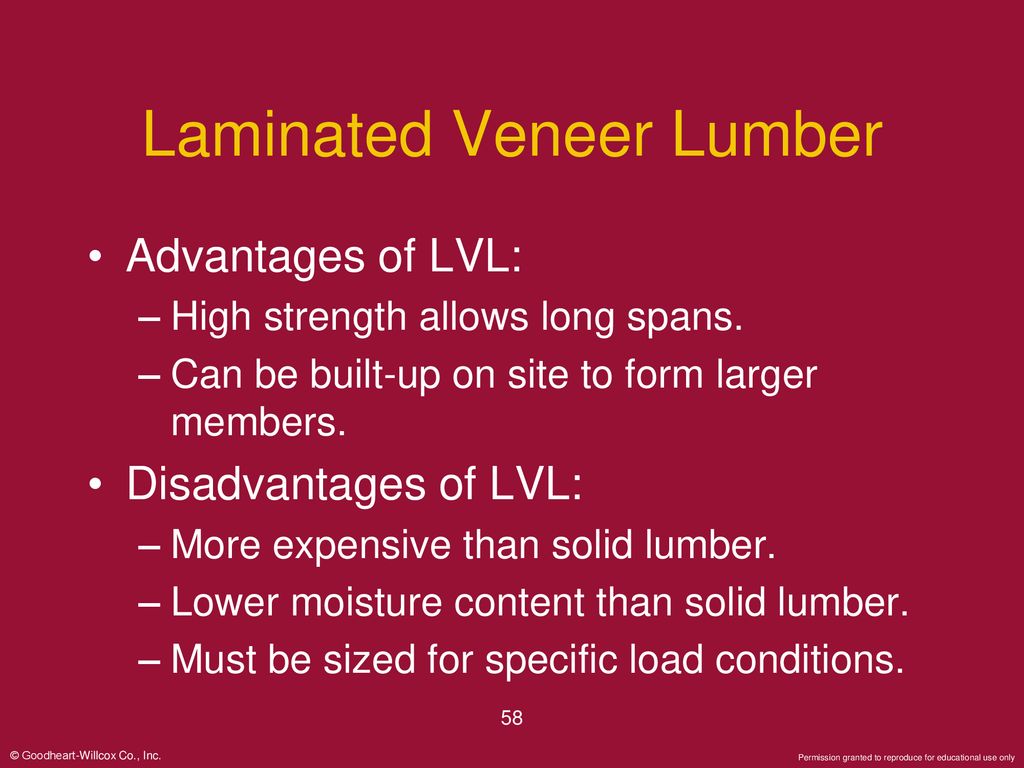

Laminated Veneer Lumber Advantages

Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives.

Laminated veneer lumber advantages. Aesthetics like natural wood with low cost. As there is scarcity of natural wood nowadays it has become expensive. Lvl offers several advantages over typical milled lumber. Made in a factory lvl is produced under controlled specifications.

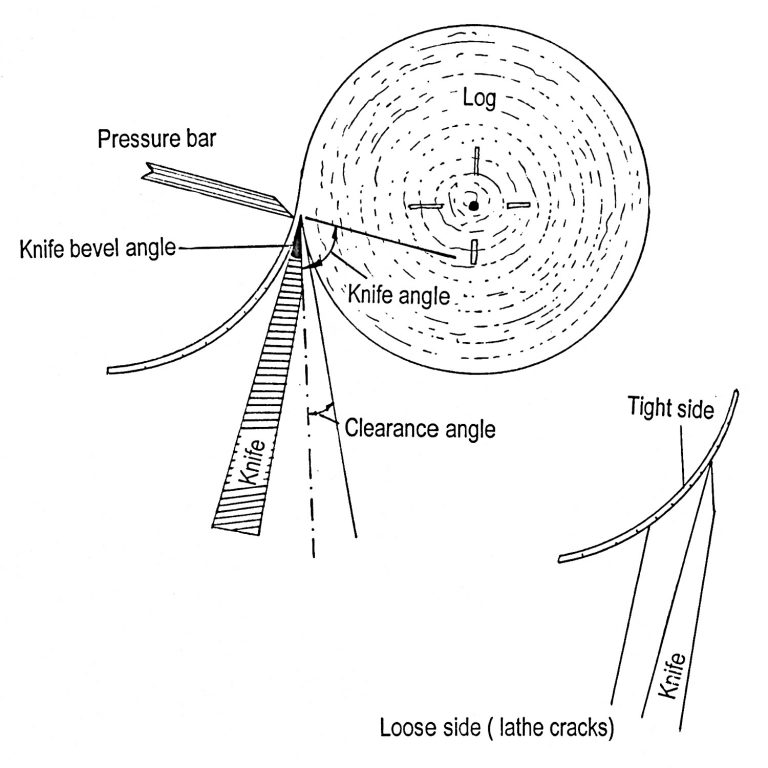

It is manufactured by bonding rotary peeled or wood veneers that have been sliced thinly under heat and pressure. It is comparable in strength to solid timber concrete and steel and is manufactured by bonding together rotary peeled or sliced thin wood veneers under heat and pressure. When engineered lumber first appeared on my radar it was in the form of i joists to solve the crowning problems 2x10 and 2x12 joists created. Advantages pros of wood veneer sheets.

They can be easily glued to an engineered wood substrate to provide wood like. Laminated veneer lumber lvl designing buildings wiki share your construction industry knowledge. Laminated veneer lumber lvl is a type of high strength engineered timber that can be used as an alternative to solid timber concrete and steel for structural applications. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives it is typically used for headers beams rimboard and edge forming material lvl offers several advantages over typical milled lumber.

Wood veneers provide aesthetics like natural wood with less cost. Lp solidstart laminated strand lumber installs like traditional framing but surpasses it in strength and consistency. Wood veneers are only thin slice of wood. Laminated veneer lumber lvl is a high strength engineered wood product used primarily for structural applications.