Laminated Spring For Railway

Buy bis is 3885 1.

Laminated spring for railway. 1 wherein one of the longest spring plates is at the top and the shortest spring plate is at the bott om. At present gbs production range has been built. Udc 625 2 012853 is. The spring consisted of a set of different length steel plates arranged with the longest at the.

Railway bogie springs. Sr 55 38 kn cm 2 the medium dynamic stress in the laminated spring max 88 3 kn cm 2 the maximal dynamic stress in the laminated spring. Flat sections specification from sai global. 9801 i 981 indian standard specification for laminated springs for railway rolling stock 1.

Traditional laminated steel suspension as applied to axlebox. Laminated bearing spring leaf spring gbs is fully geared to supply any type of lb spring to highest quality standards with a production capacity of nearly 5940 mt p a. Line of the critical stress of the laminated spring is obtained red line 1. Air spring for railway vehicle.

1992 r2007 steel for the manufacture of laminated springs railway rolling stock part 1. Scope covers the requirements for laminated springs used for railway rolling stock. Manufacturer of leaf springs laminated leaf springs industrial leaf springs multi leaf springs offered by asha spring engineering company howrah west bengal. Leaf laminated steel springs mounted on the axles upon which the vehicle body rested.

Improvement of low temperature properties of rubber material for diaphragm 3 1 target performances. The flat plates are called leaves of the spring. Application of spiral spring. Making laminated railway springs from brochure of the visit of george v and queen mary to cammell laird grimesthorpe steel and ordnance works 1918 original at sheffield archives sy529 1.

For the purpose of illustration the spring and all the separate parts thereof will be described inv the position shown in fig. 64 air springs for railways available for very cold environments 3. On the other hand the loads during the exploitation cause the stresses in the laminated spring of the following intensities. Laminated rubber air spring metal fitting air compressed fig.

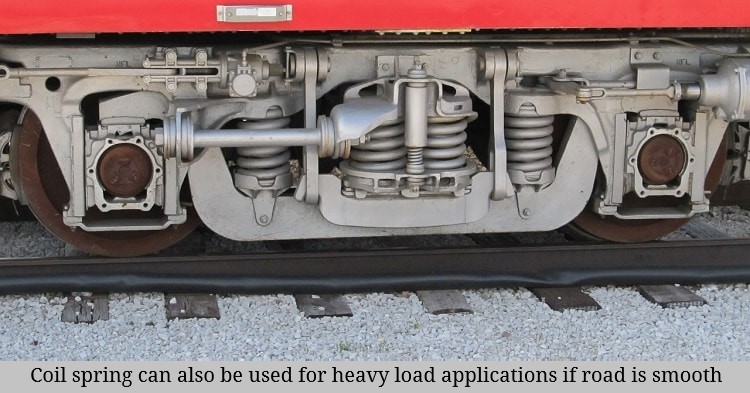

Railways in the uk used the same principle as shown in figure 1. Multi leaf spring is widely used for the suspension of trucks and railway wagons. Terminology given in is. Call 08048601374 63 response rate.

The laminated spring embodying the present invention is indicated generally by the reference numeral i.