Laminated Plastics Definition

Bonding agents include phenol formaldehyde resins polyesters epoxy resins and polyimides.

Laminated plastics definition. Laminated plastics is the premiere industry leader for full line distribution and advanced fabrication of plastic materials serving a wide variety of industries and applications. A laminate is a permanently assembled object created using heat pressure welding or gluing. Unlike traditional plastics which are usually manufactured from some form of virgin resin laminating sheets offer distinct performance characteristics by combining two different material types into one. Plastic laminate a laminate made by bonding plastic layers formica any of various plastic laminates containing melamine laminate a sheet of.

Contact laminated plastics for answers to your plastics distribution and fabrication needs. Laminated plastic a material consisting of several sheets referred to collectively as filler of fabric paper wood fiber or fiber mat impregnated with a synthetic resin bonding agent. Plastic laminate adhesive or resin is then used to add a decorative paper or melamine top layer. Consisting of several thin layers of.

Composed of thin sheets of plastic wood etc superimposed and bonded together by synthetic resins usually under heat and pressure. Covered with a thin layer of plastic to protect it. Laminated plastic definition is a plastic made of superposed layers of paper wood or fabric bonded or impregnated with resin and compressed under heat. Plastic laminate is a composite building material made from kraft paper resin and adhesives.

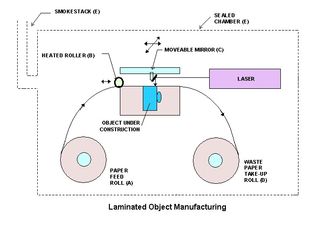

Lamination is the technique process of manufacturing a material in multiple layers so that the composite material achieves improved strength stability sound insulation appearance or other properties from the use of the differing materials such as plastic. Multiple layers of kraft paper are soaked in resin then pressed together at high levels of temperature and pressure to form a single sheet.