Laminated Object Manufacturing Uses

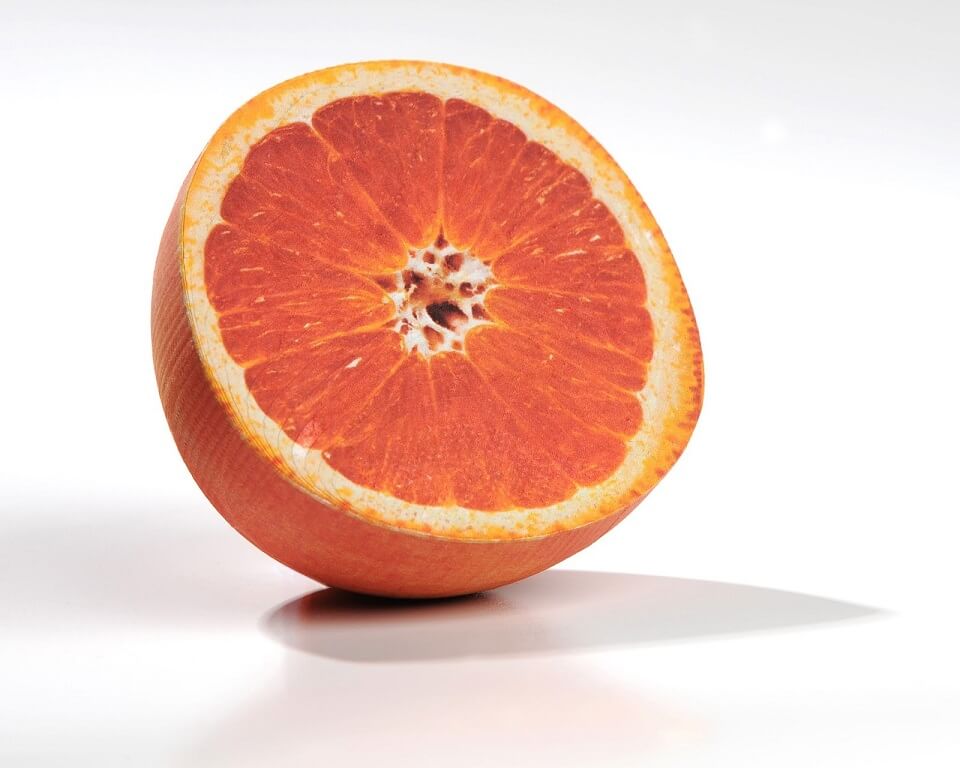

The process is quite useful for making visual models speedily at low cost.

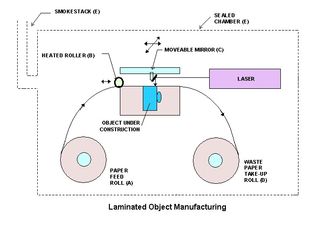

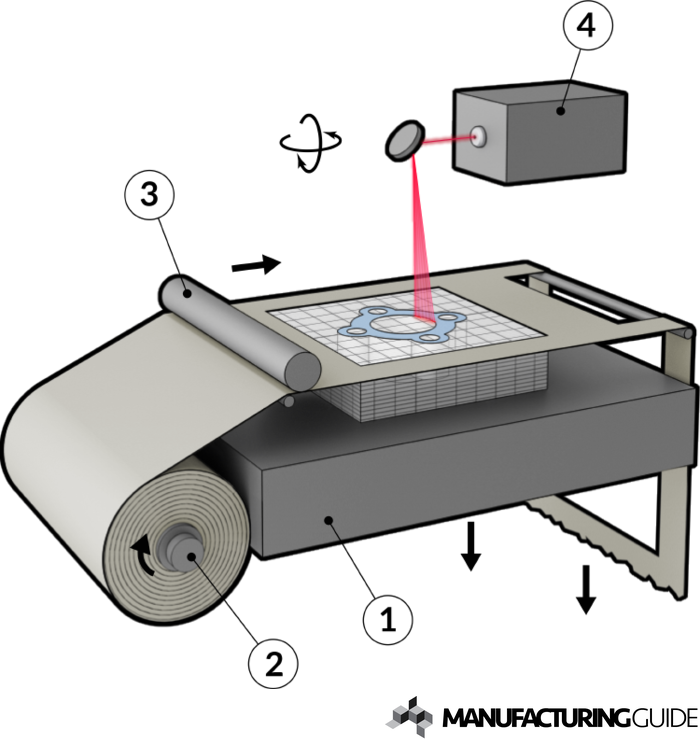

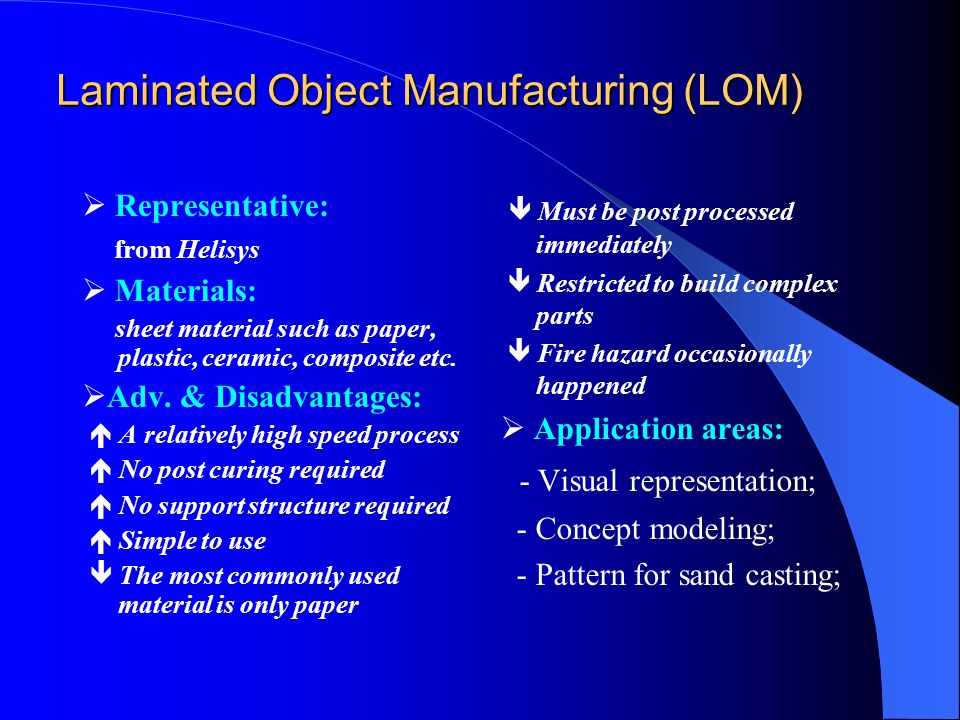

Laminated object manufacturing uses. Layers of material plastic or layers paper are fused or laminated together using heat and pressure. The laminated objects manufacturing 1. Laminated object manufacturing is a 3d printing method developed by helisys inc now cubic technologies. The process is however not suitable for making structural or.

Laminated object manufacturing is a method of 3d printing in which layers of plastic or paper are fused together using heat and pressure and then cut into the desired shape with a computer. What is laminated object manufacturing. Laminated object manufacturing lom is a rapid prototyping system developed by helisys inc. Sheet lamination is a low temperature process and is used for making models for display.

But what happens during this process. A droplet deposition manufacturing b fused deposition modeling c laminated object manufacturing d selective laser sintering e stereolithography or f three dimensional printing. Later a diffusion welding process is used join the foils. Laminated object manufacturing is a lesser known additive manufacturing process where an object is created by successively layering sheets of build material bonding them through heat and pressure and then cutting them into the desired shape using either a blade or a carbon laser.

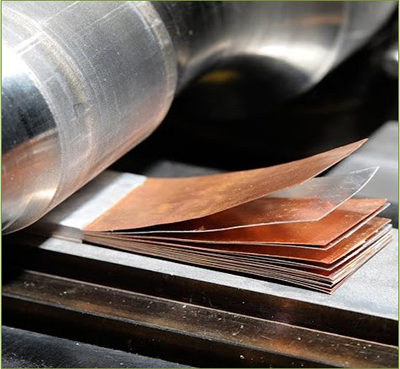

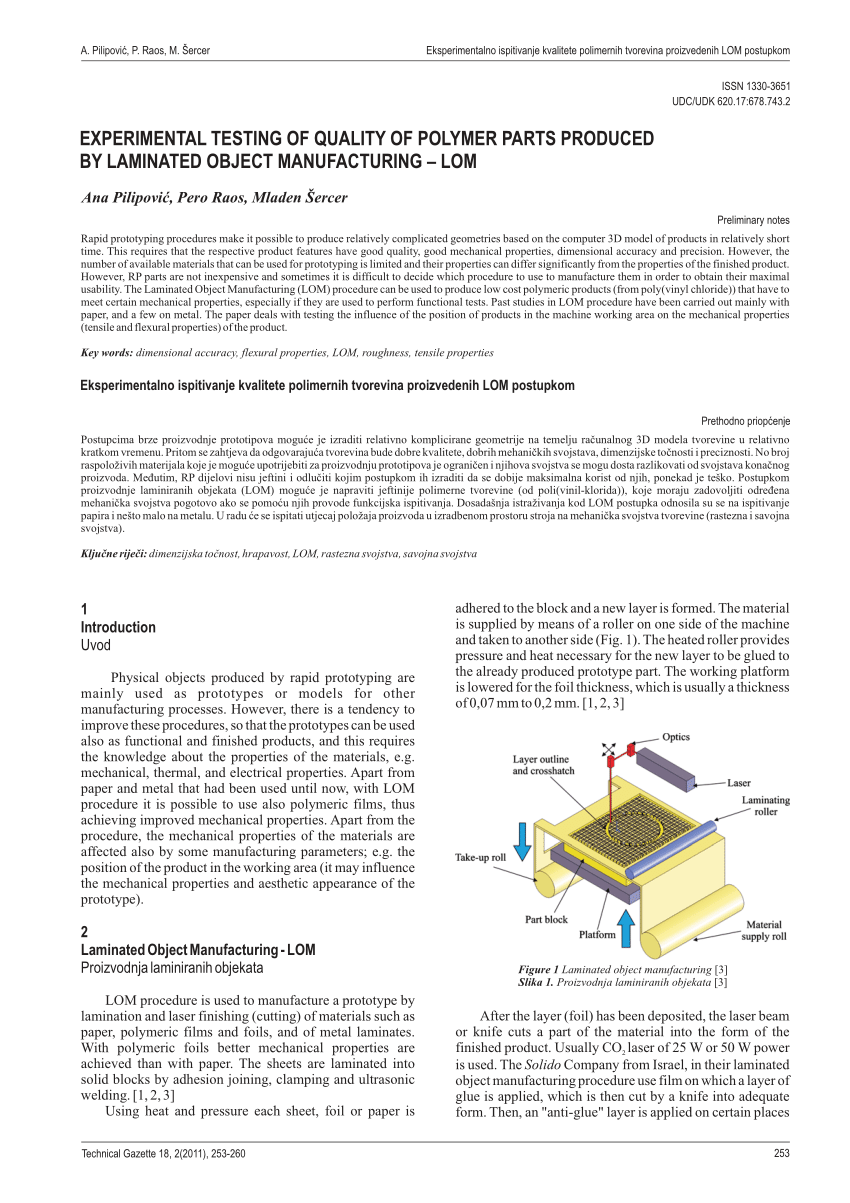

Feed spindle supplies the material and a take up spindle controls. Laminated object manufacturing lom uses a laser beam pulsed nd yag to cut the desired shape in a metal foil in this example in steel. 1 it is type of solid rapid prototyping used to create low cost 3d model using lasers 3. Lom equipment and process 4.

So if the joining process is good the strength of. 29 8 which one of the following rp technologies uses solid sheet stock as the starting material. More specifically a foil coated with adhesive is overlaid on the previous layer and a heated roller heats the. Laminated object manufacturing lom and ultrasonic additive manufacturing uam are two sheet lamination methods.

The objective is to enhance the mechanical stability towards the properties of the used material. Lom excels at creating objects ideal for visual or aesthetic modeling. You may have never heard of this 3d printing technology before and that is normal. The laminated object manufacturing involves an additional cross hatching process to remove the extra build ups.

Lom uses alternate layers of paper and adhesive while uam employs thin metal sheets conjoined through ultrasonic welding. Hybrid process which involves adding and subtracting material to create a part 2. Cubic technologies is now the successor organization of helisys in it layers of adhesive coated paper plastic or metal laminates are successively glued together and cut to shape with a knife or laser cutter objects printed with this technique may be additionally modified by machining or drilling.