Laminate Vs Build Up Substrate

When laying it is mandatory to build a substrate under the laminate on the walls this will ensure the preservation of safety and durability.

Laminate vs build up substrate. If the material is damaged then in case of detection of damaged areas it should be covered with an additional layer of a substrate under the laminate. Over time they open up with expansion and contraction and you get moisture between them and then swelling starts. Low stress connections sld ti lfil jit d t t h d hyperbga compliant laminate overview ceramic solder column hyperbga lid. Laminate flooring is simple to keep clean and can handle regular foot traffic with ease but laminate planks are not waterproof.

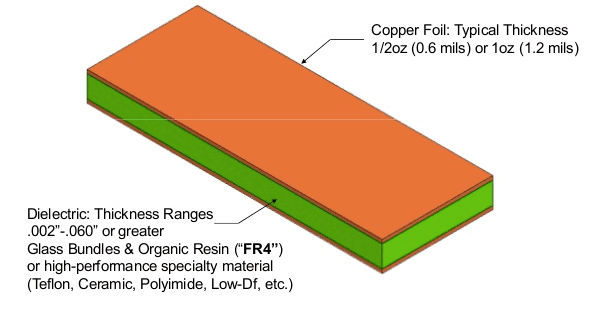

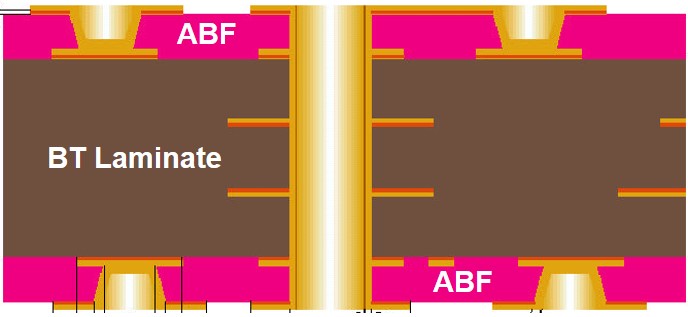

Examples include high performance mobile devices including 5g infotainment and adas for automotive and artificial intelligence further the benefits from low inductance and increased routing density enable optimized electrical paths for high frequency signals making fccsp. To keep a laminate floor looking clean all that is needed is a soft broom a damp mop or brush tipped vacuum wand. Laminate packages employ a bga design which utilizes a plastic or tape laminate substrate over a leadframe substrate and places the electrical connections on the bottom of the package rather than around the perimeter. High humidity or moisture prone areas can lead to permanent damage of a laminate floor.

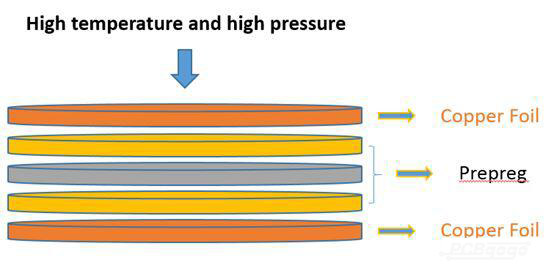

This paper reviews sequential build up sbu laminate substrate development from its beginning in 1988 and reports on developments in this technology for ibm applications since its adoption in 2000. Caulking after the fact just separates. A core build up layers and finishing layers. Attach 4 inch wide plywood build up strips around the perimeter underside of the counter and along any seams.

It reports on developments in this technology for ibm applications since its adoption in 2000. Build up substrate ic packages ic lead frames related to the recent performance improvement of electronic devices using build up substrates produced by the direct laser lamination dll process have seen increases in demand due to achieving the dual benefits of higher speed and higher density. The fccsp package is an attractive option for applications in which both performance and form factor are critical. This paper reviews sequential build up sbu laminate substrate development from its beginning in 1988.

It s happening in my house now house is less than five years old and no i didn t build the tops but will have to replace them soon thanks to the short cuts. Use a block plane to trim the build up strips flush with the counter edges. Thin core build up 10 layer substrate 2 9 thin core build up 6 layer substrate 2 0 deformation analogy consider solder column array deformations between ceramic card hyperbga laminate internalizes deformations.