Laminate Bending Process

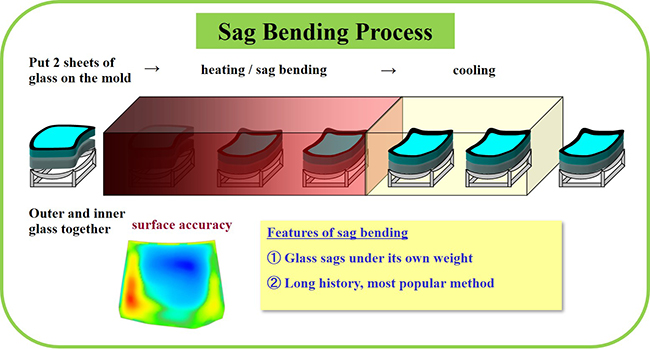

Since heat bending laminate is a more difficult process measure the curve of your counter using step one from the cold bending method.

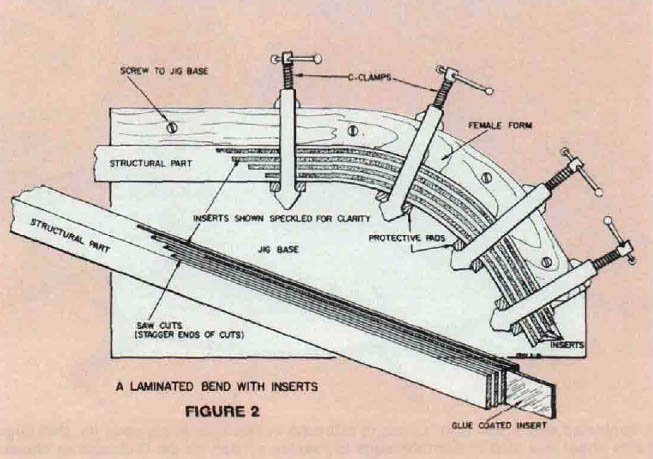

Laminate bending process. There are many ways to construct a form and apply pressure. Steaming wood to the required curve 3. With glue between each lamination a press is used to bend the bundle of laminations around a form. As we all know the thinner the part the easier it will conform to a curve.

Cut the plies through a straight grained edge rather than the face grain side. Because the cuts are made parallel to the grain a straight grained board can be sliced and put back together with little interruption to the grain lines. Line bending is a thermoforming or heat forming process which involves heating a thermoplastic sheet material over a strip heater until it becomes soft and pliable. Actually there s no magic required.

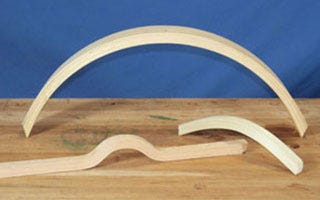

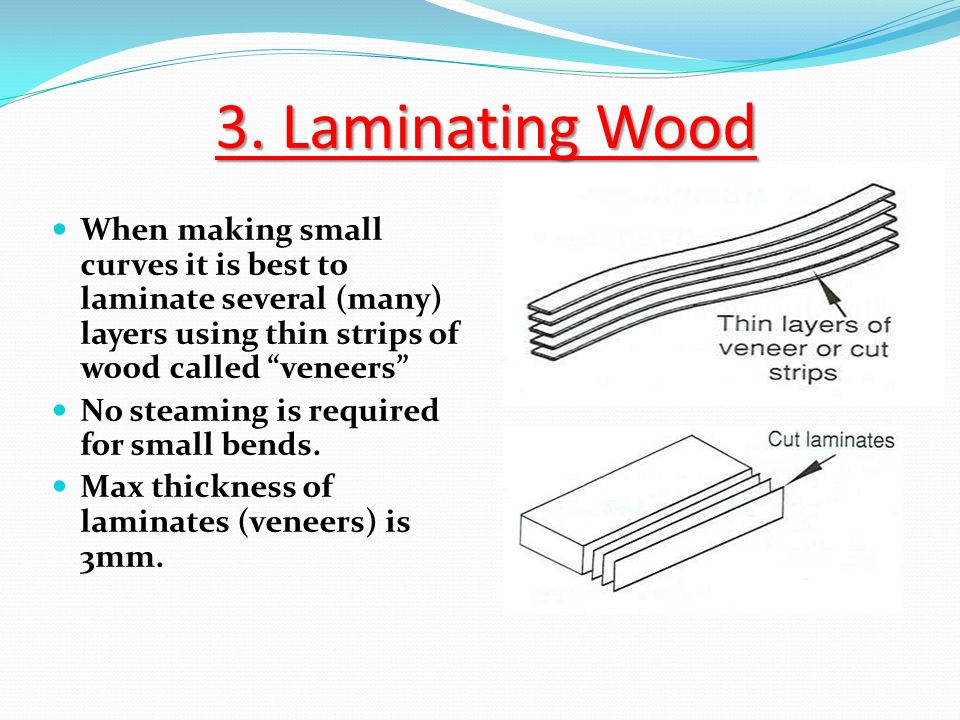

After using an oscillating sander to clean up the inner curves and a disc sander to clean the outer curves trace your shape to another mdf board using your sanded shape and then rough cut the same shape only this time leave at least 1 16 of an inch between your cut and your pencil line. We started this wood bending series exploring simple and kerf bending. Laminate several many layers using thin strips of wood called veneers. Line bending is an efficient process for creating one or multiple tight radius bends in most formable sheet plastics.

For instance laminated wood is resistant to warping or twisting due to its manufacturing process. Just a saw some wood some glue and a few time tested techniques. Laminated wood can be made of hardwood or softwood depending on the needs of the customer or from different kinds of wood to mix and match their strengths such as the outer layers of a softwood for a certain look with the inner layers of a. So the first order of business is to build the form followed by cutting the wood into lamination strips.

If the radius is three inches or greater you may be able to bend your laminate without heating it. The term postforming is used to describe the bending process applied to specially developed grades of laminate which whilst possessing all the well known properties of standard grade high pressure laminates can also be formed into simple cylindrical concave or convex curves. Gluing thin veneers strips of thin wood together to form the curve. In this edition we look at forming wood parts using thin laminates.

Lamination is the process of bending many thin parts together and holding them in the desired shape until the glue between them. Plastic bending can be accomplished using several techniques. Learn how to make wood magically bend to your will.