Laminar Air Flow Vs Unidirectional Airflow

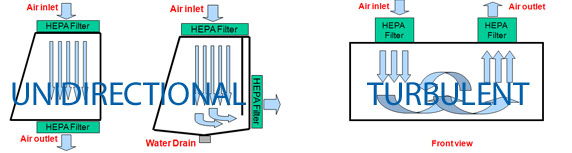

The official naming of laminar flow is unidirectional airflow and refers to an airflow in one direction at the same speed without interruption due to turbulence.

Laminar air flow vs unidirectional airflow. Unidirectional flow is maintained in cleanrooms through the use of laminar air flow hoods that direct air jets downward in a straight path as well as cleanroom architecture that ensures turbulence is lessened. Stainless steel or other non shedding materials are used to construct laminar air flow filters and hoods to prevent excess particles entering the air. Original content from critical point www criticalpoint info. Laminar air flow refers to air that flows in a straight unimpeded path.

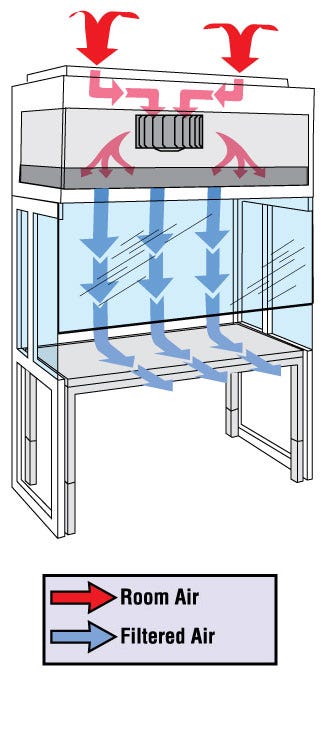

Laminar flow systems direct filtered air downward or in horizontal direction in a constant stream towards filters located on walls near the cleanroom floor or through raised perforated floor panels to be recirculated. Is there a difference between uni directional flow and laminar flow. Turbulent or non unidirectional air flow uses both laminar air flow hoods and nonspecific velocity filters to keep air in a cleanroom in constant motion although not all in the same direction. Laminar flow cabinets are used in a wide array of applications in the pharmaceutical medical manufacturing and scientific research fields.

Laminar air flow systems should provide a homogeneous air speed in a range of 0 36 0 54 m s guidance value at the working position in open clean room applications. Part grade a stated that laminar air flow system should provide a homogeneous air speed in a range of 0 36 0 54 m s guidance value at the working position in open clean room aplication. Laminar flow enclosures can be configured to provide vertical or horizontal airflow depending. Unidirectional airflow utilises hepa filters to filter and clean all air entering the environment.

Asking this question because annex 1 to eu gmp point 3. The maintenance of laminarity should be demonstrated and validated. A uni directional air flow and lower velocities may be used in closed isolators and glove boxes. Clean benches with either vertical or horizontal laminar airflow provide the cleanest working environments because hepa filtered air within these benches is unidirectional and turbulence free.

The maintenance of laminarity should be demonstrated and validated. Watch the airflow differential between turbulent and unidirectional airflows demonstrated by smoke in a pharmacy isolator to understand the benefits of unidirectional flow.